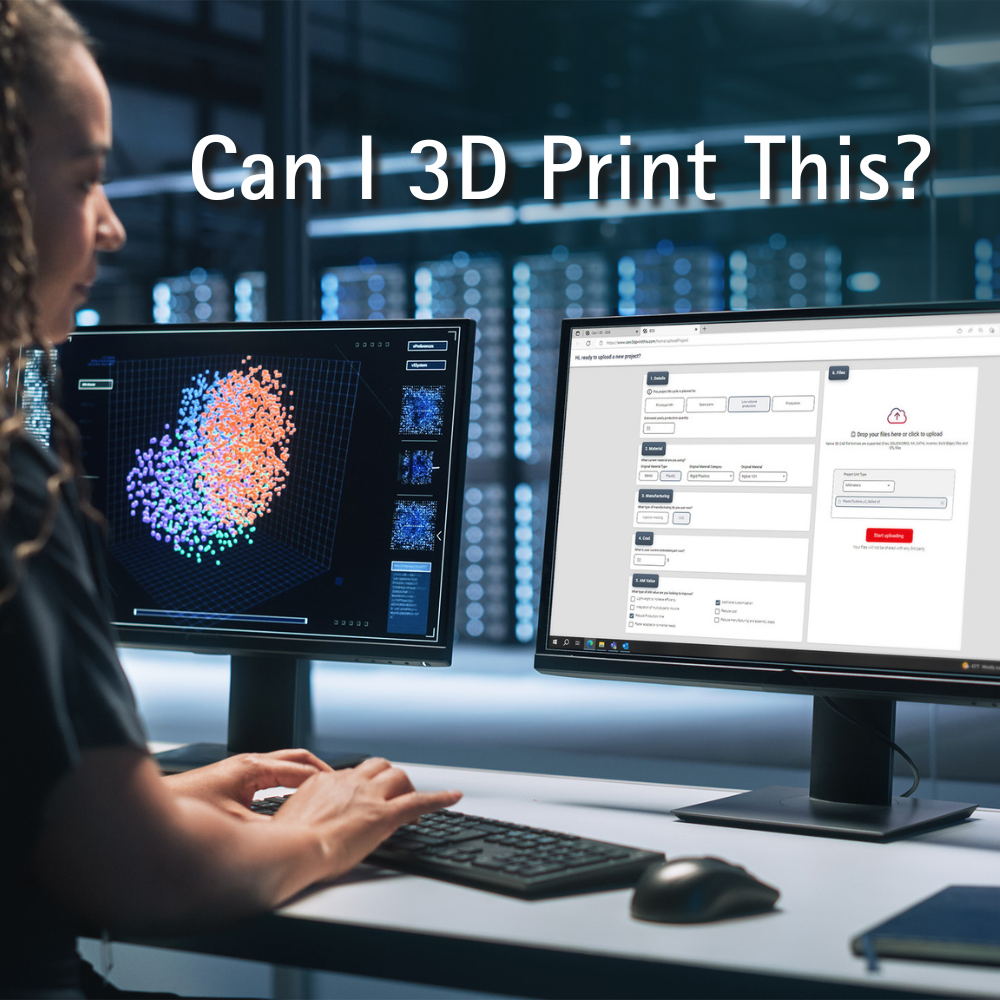

Can You 3D Print That? The Story Behind the New EOS North America Online Analysis Tool

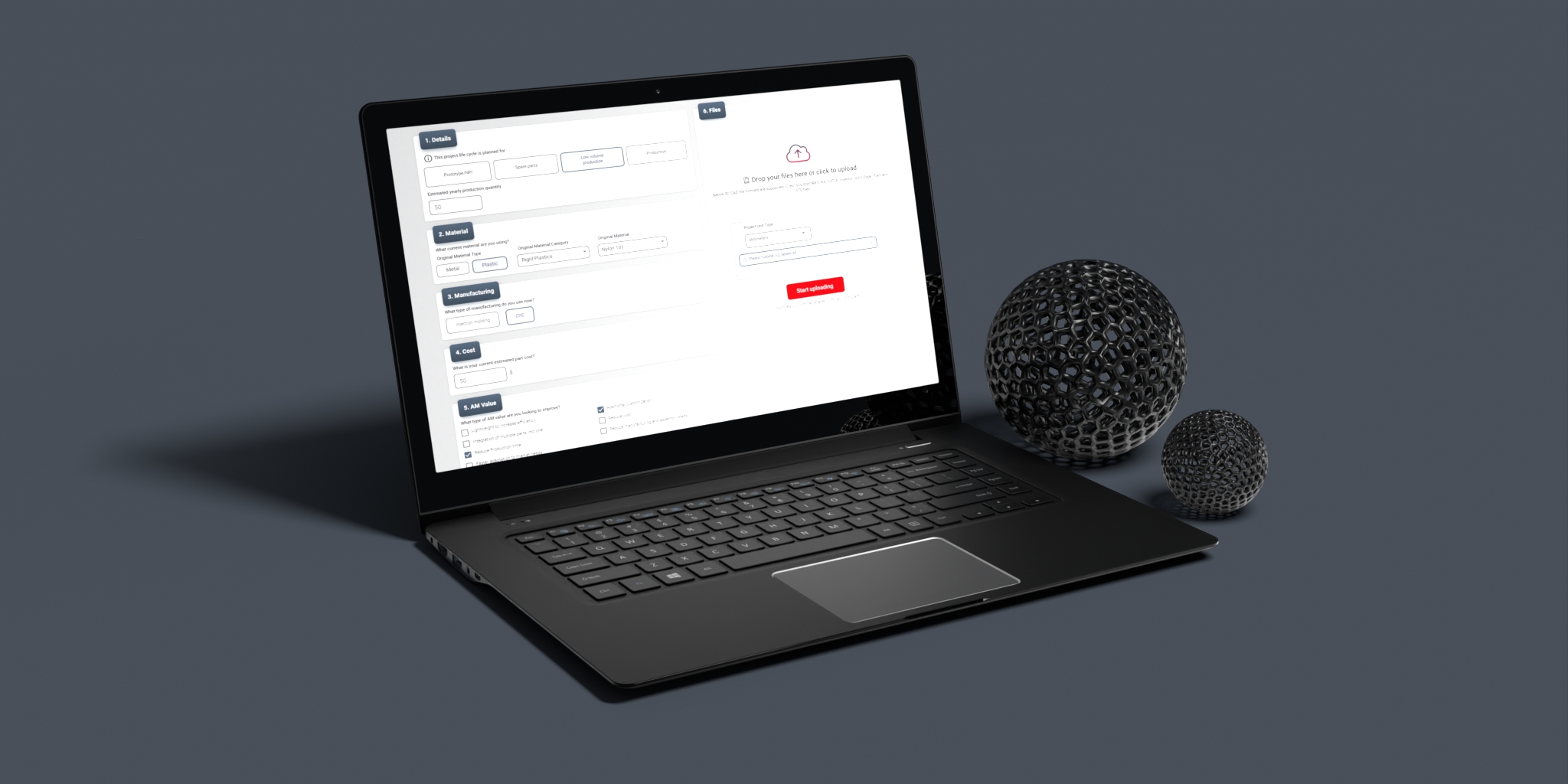

The EOS North America Additive Minds team recently unveiled our new online analysis tool, Can I 3D Print This. Can I 3D Print This is built to enable organizations that are exploring additive manufacturing (AM) to answer questions on their own time, about the parts they’re specifically interested in manufacturing with industrial 3D printing. The tool empowers companies to take industrial 3D printing education into their own hands – with Additive Minds waiting in the wings to jump in and help.

Why create Can I 3D Print This?

The Additive Minds team, also known as the technical consulting department of EOS, specializes in assisting organizations meet their goals with industrial 3D printing. One of the most common questions the Additive Minds team encounters when working with potential or first-time AM users is the namesake of this tool, ‘Can I 3D Print This?’ Answering this common question independently empowers the user and allows an Additive Minds team member jump in when needed with a goal already set – allowing them to create a plan to integrate AM for their application.tion.

Streamlining the Additive Minds process with the help of Can I 3D Print This also allows potential new AM users to:

- Have independence in their research of industrial 3D printing before engaging with the EOS team

- Understand the factors, such as material science and AM system size in relation to number of applications produced per build that can change cost-per-part (CPP) when leveraging EOS technology

- Share the Can I 3D Print This report with others within their organization who may be the decision makers in adding new manufacturing technology to their production line

How did EOS build the tool?

EOS partnered with CASTOR, a software company that enables organizations to optimize manufacturing and increase profitability by using industrial 3D Printing. CASTOR solves the challenge of identifying where, when, and how to utilize the benefits of 3D Printing, by automating the process of screening parts and highlighting the ones that make a strong business case from a financial, supply chain, and sustainability perspective. Its advanced capabilities provide redesign suggestions such as part consolidation and weight reduction. Castor’s software integrates the results derived from the analysis of more than 30,000 parts by more than 80 companies, including Fortune 500 organizations.

Can I 3D Print This is a straightforward, empowering tool for those interested in learning more about the possibilities unlocked by AM. If you’re interested in leveraging the tool, keep reading to understand how the tool works and what is needed to get started.

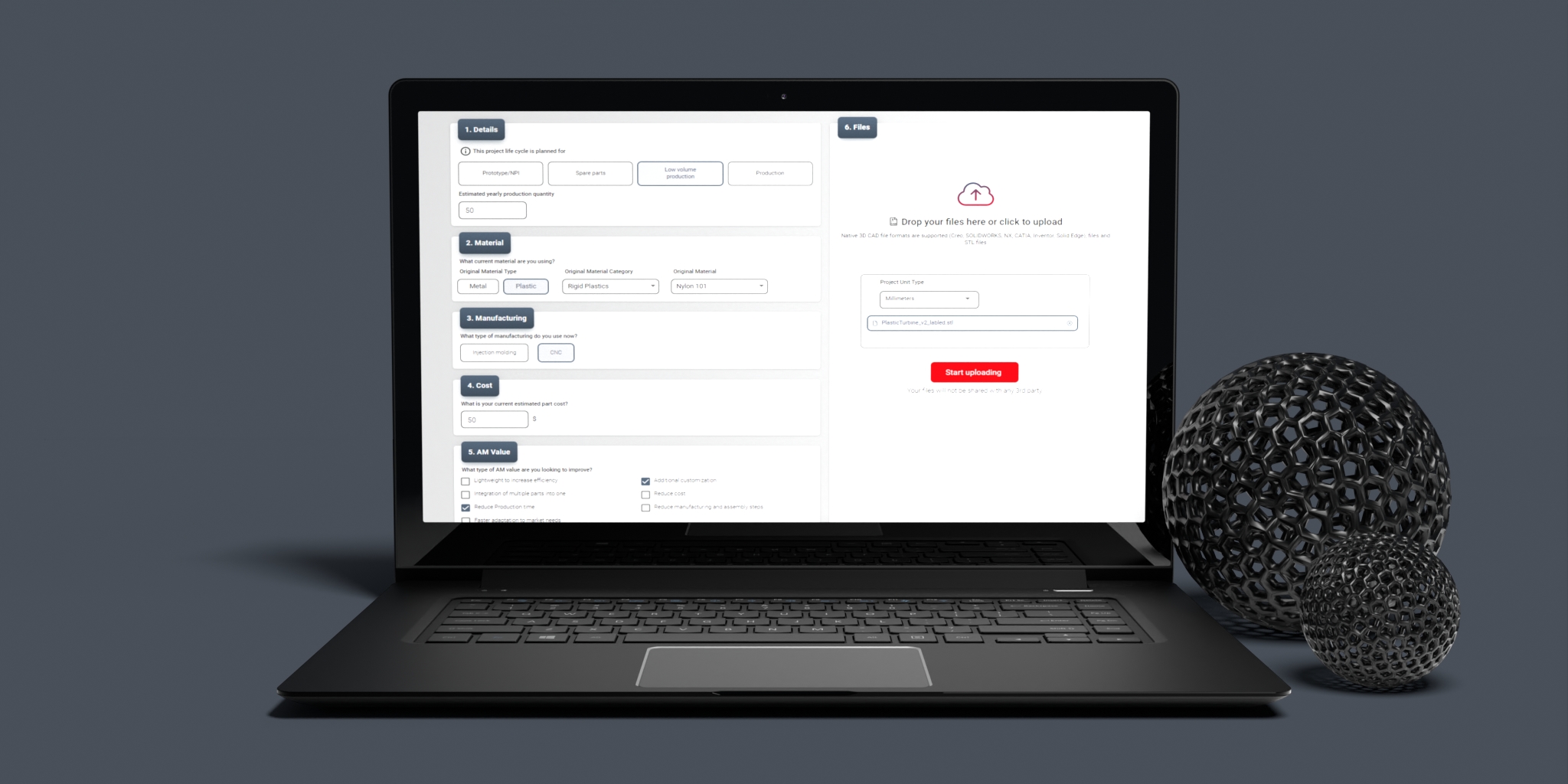

What information is needed to upload a part to Can I 3D Print This?

- Your basic goals for the application project’s life cycle such as prototyping/NPI, spare parts, low volume production, or production

- The material you are currently using to produce the application, whether it is metal or plastic, and the material category and name

- The manufacturing process you’re currently using, such as injection molding or CNC machining

- The current estimated cost of producing one of your parts

- The value you’re looking to improve with AM, i.e. lightweighting, part consolidation, reduced production time, faster prototyping, customization, cost reduction, or reduction of assembly steps

- Lastly, you will need to have a native 3D CAD file of your application – Creo, SOLIDWORKS, NX, CATIA, Inventor, Solid Edge, and STL files are all supported

What is included in the report after upload?

- The cost estimation of leveraging industrial 3D printing for part production, including the production time, recommended printer, and recommended AM material

- Total cost, production time, and material comparison analysis of leveraging industrial 3D printing vs. your current manufacturing strategy

- A cost parameter, material, and geometry analysis, including any changes to the part that may need to be made to improve AM results

- A financial break-even analysis of 3D printing vs. your current manufacturing strategy

- A production time analysis of 3D printing vs. your current manufacturing strategy

FAQs of Can I 3D Print This

Who can use Can I 3D Print This?

Anyone within the United States, Mexico, or Canada can use the Can I 3D Print This online analysis tool. If there is demand for the tool to be expanded globally, EOS is open to exploring global solutions.

How many parts can I upload to Can I 3D Print This?

Each user account is limited to the upload of five parts and will remain active for 30 days. If you have more than five parts you would like to analyze or would like to extend your license, the Additive Minds team is still able to assist. Connect with an Additive Minds team member to talk about your part files and leveraging AM for production by submitting an inquiry here or through the Can I 3D Print This platform.

What if my file type is not supported for upload?

If your file type is not supported for upload, there are many options to convert application files. Some non-STL file types are also accepted. The All3DP article on STL file converter platforms includes multiple options for file conversion: The Best STL File Converters (Many Are Free) | All3DP

How can I get in contact with the Additive Minds team after using the Can I 3D Print This tool?

To chat with an Additive Minds team member about your Can I 3D Print This analysis results, request a meeting with Additive Minds through the Can I 3D Print This platform or a general inquiry here where a team member is able to walk through your results with you and share next steps in the 3D printing process if you’re interested in moving forward.

For more information, visit CanI3DPrintThis.com