06/10/2021

The consumer space is hyper-competitive, with manufacturers continuously searching for differentiation and unique reasons for customers to choose their brand. The ability to tailor products to the individual is a massive selling feature and that ability is possible with 3D printing. Traditionally, production of eyewear required dies and molds and may have been limited in choice to “small, medium, or large” and offered in a few colors. Now, with scanning software and using common hardware, entire batches of eyewear can be produced with each pair unique to each person, and requiring no molds, and produced on-demand.

Energy

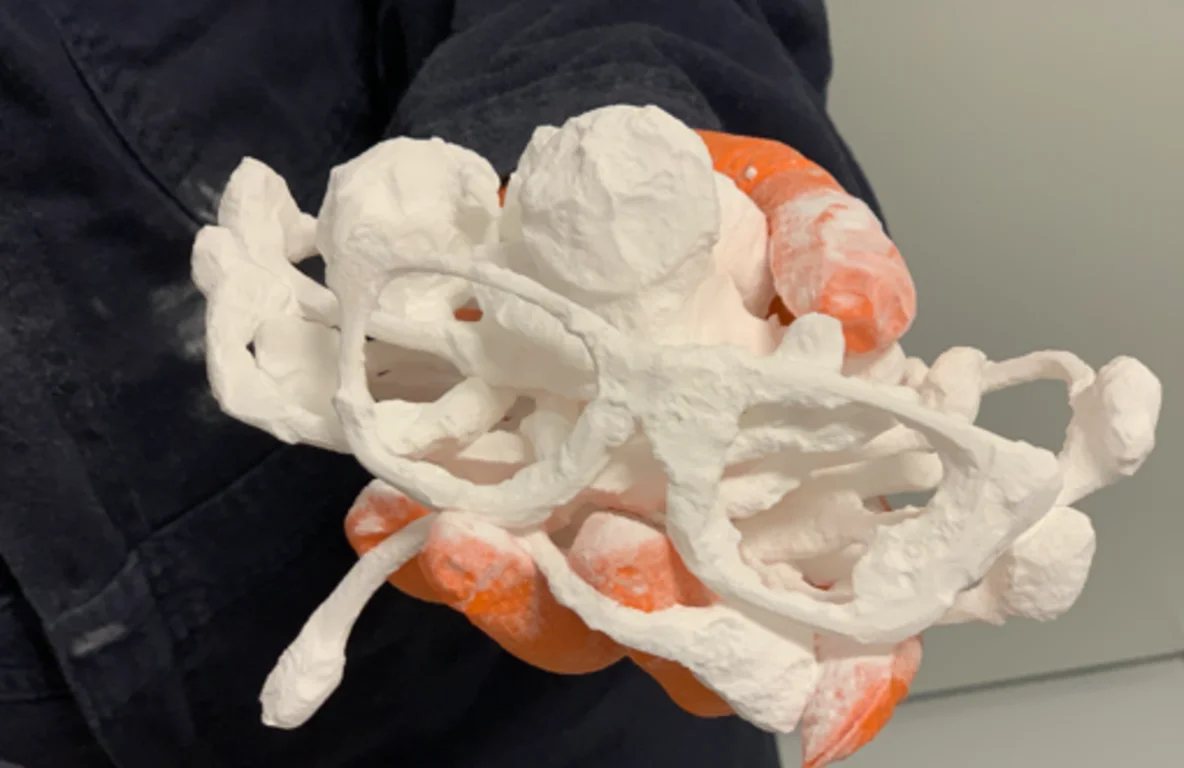

Medical