KEY BENEFIT

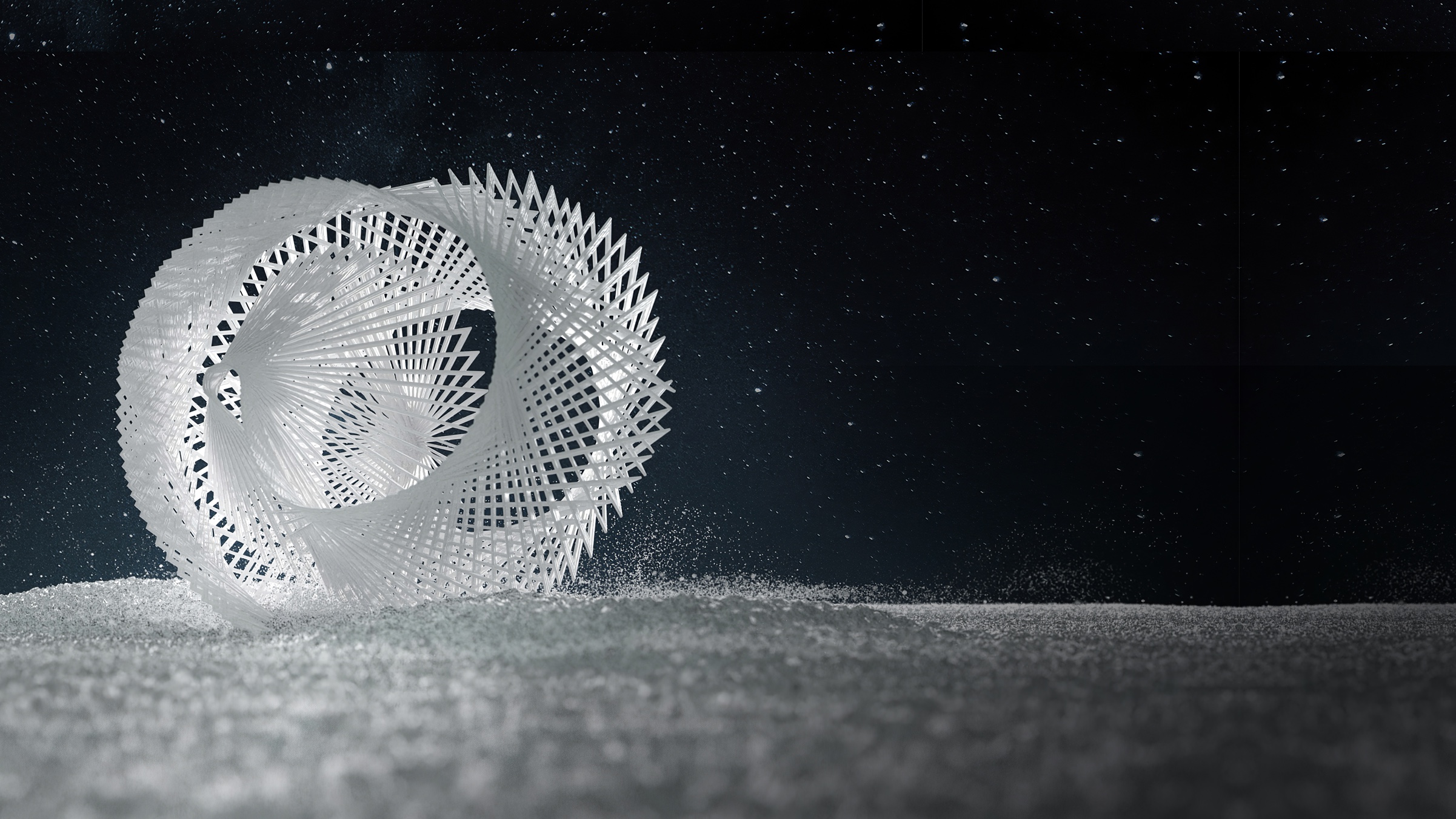

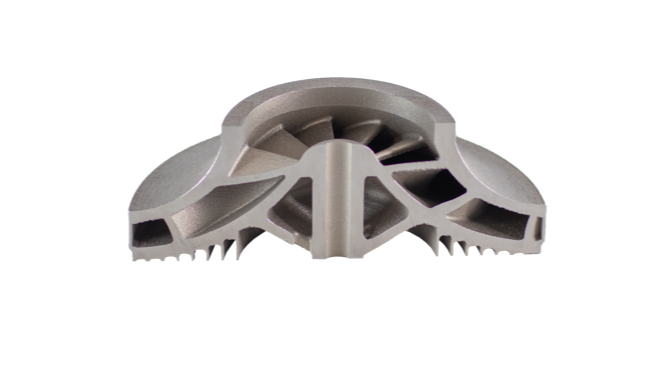

Additive manufacturing transforms and disrupts.

Lead the change in your business.

KEY BENEFIT

"At EOS we always strive to push the boundaries of innovative manufacturing. We encourage our partners to look toward a future where production is less harmful to our planet without having to sacrifice excellence in design and functionality."

Björn Hannappel

Head of Sustainability, EOS Group

KEY BENEFIT

Learn more in blog article: "Why 3D Printing is Responsible Manufacturing"

KEY BENEFIT

Learn more in blog article: "Reinventing the Eyewear Industry"