PLASTIC PLATFORMS

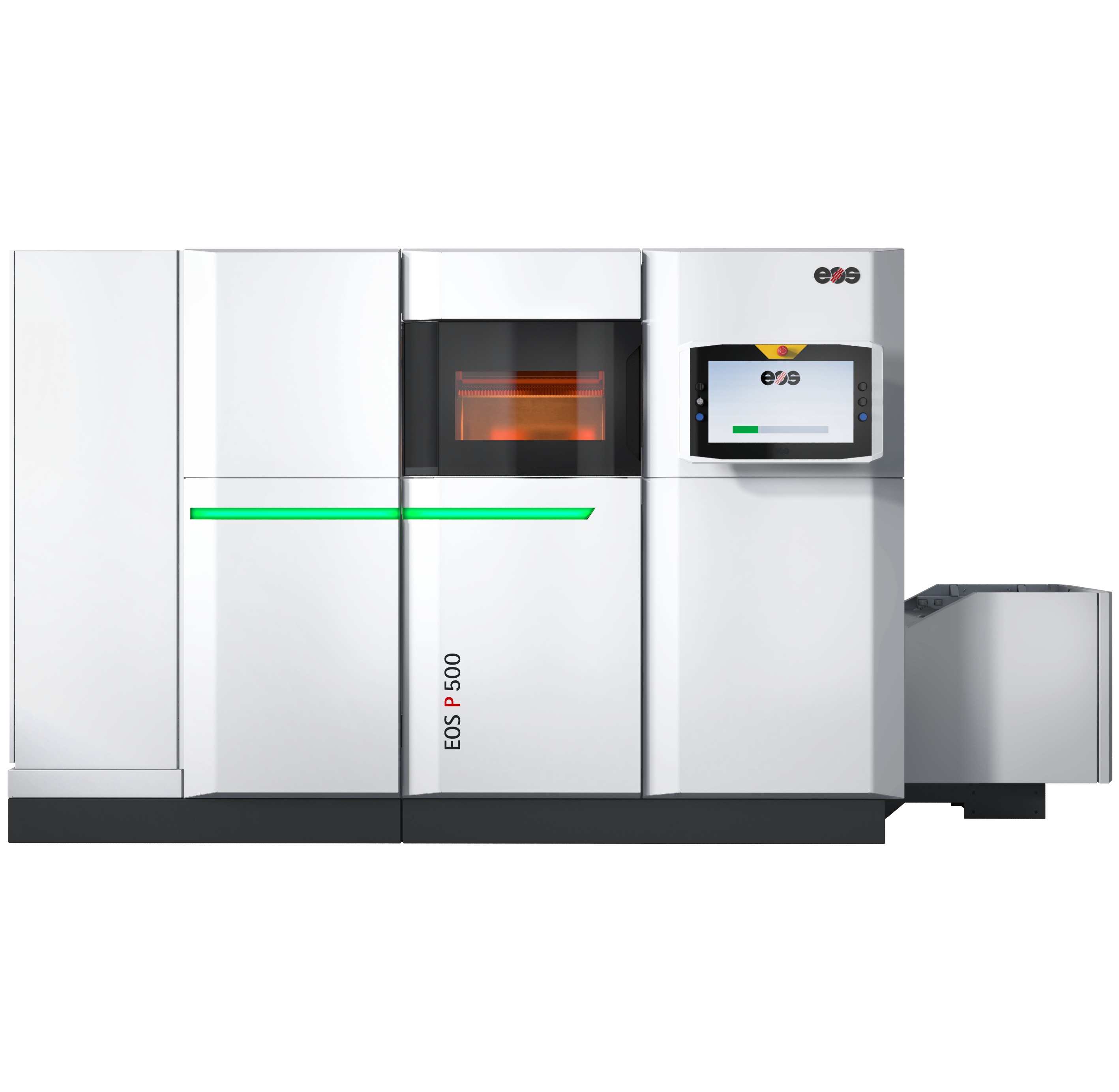

EOS P 500

The Fastest and Most Cost-Effective Industrial-Scale Platform on the Market

With support for a wide array of materials, it is the ultimate additive manufacturing platform for laser-sintered plastic parts on an industrial scale.

Key Features

Low Cost-Per-Part

The EOS P 500’s two powerful lasers and innovative recoating system help reduce cost-per-part at industry-best levels.

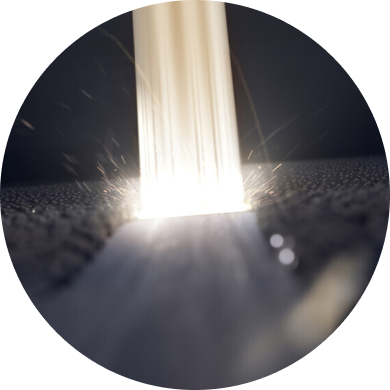

Laser-Fast

Over an ample 500 x 330 x 400 mm build volume, two 70-watt lasers achieve the industry’s fastest build rate of 6.6 liters per hour.

Excellence on Autopilot

Automated interfaces and optimized accessories reduce cycle times and guarantee quality build times lasting several days.

Perfectly Reliable

A three-stage filter unit and intelligent management of thermal properties and gas flow ensure optimal process conditions.

Key Benefits

-

Cost Reduction

-

Intuitive Integration

-

Incredible Versatility

Technical Data

-

Construction Volume

-

Laser Type

-

Precision Optics

-

Scan Speed

-

Power Supply

-

Machine Dimensions (W x D x H)

-

Recommended Installation Space

-

Weight

-

Software